Xawaaraha la hagaajin karo iyo kala firdhiye hawleedka deggan

Faahfaahinta Alaabta

Qaybiyaha ayaa lagu heli karaa qiyaaso iyo noocyo kala duwan, qaybaha xiriirka la leh alaabta, sida taangiga walaaqaya iyo saxanka kala firdhiya, waxay ka samaysan yihiin bir aan fiicnayn. Marka loo eego shuruudaha macaamiisha, matoorada aan qarxin waxaa loo isticmaali karaa matoorada wadista.

Xawaaraha ugu badan ee qalabku wuxuu gaari karaa 1450rpm, xawaaruhuna wuxuu ka sarreeyaa 20m / s, kaas oo si dhakhso ah oo siman u kala firdhi kara budada walxaha dareeraha ah; Qalabka ayaa si siman u kala firdhiyey sababtoo ah xoogga xiirid ee aadka u sarreeya, samaynta saameyn wanaagsan oo Levitation ah.

Iyadoo loo marayo wareegga xawaaraha sare ee saxanka kala firdhiyey, maaddadu waxay ku socotaa qaab wareeg ah, waxay abuurtaa vortex xoog leh, waxayna hoos ugu soo degtaa xagga hoose ee vortex qaab wareeg ah. Saamaynta xiirid xooggan iyo is-jiidhka ayaa ka dhex abuurma qaybaha si loo gaaro shaqooyinka kala firdhinta degdega ah, kala dirida, isku darka labbiska iyo emulsification.

Qulquliyaha Haydarooliga waxaa kor iyo hoos u kaxeeya bamka biyo-mareenka, isagoo wada habka gudbinta oo dhan iyo kooxda shaqada kor iyo hoos.

Codsiga

Disperser waxaa loogu talagalay in lagu qaso walxaha adag dhexdhexaadka ah ee warbaahinta dareeraha ah. Kala dirida waxaa loo isticmaalaa soo saarida rinjiyada, xabagta, alaabta la isku qurxiyo, koollada kala duwan, kala firdhiso iyo emulsion, iwm.

Soosaarayaasha waxaa lagu samayn karaa noocyo kala duwan. Qaybaha iyo qaybaha xidhiidhka la leh alaabta waxay ka samaysan yihiin bir aan lahayn. Codsiga macmiilka, qalabka ayaa weli lagu soo ururin karaa darawal aan qarxin

Soosaaruhu wuxuu ku qalabaysan yahay hal ama laba kicin - nooca qalabka xawaaraha sare ama jir-xawaaraha hooseeya. Tani waxay ku siinaysaa faa'iidooyinka habaynta walxaha viscous. Waxa kale oo ay kordhisaa wax soo saarka iyo heerka tayada kala firidhsanaanta. Naqshaddan millatariga waxay kuu ogolaaneysaa inaad kordhiso buuxinta markabka ilaa 95%. Ku-buuxinta walxaha dib loo warshadayn karo ee diiradda-saaran waxay dhacdaa marka maaskada la saaro. Intaa waxaa dheer, wareejinta kulaylka ayaa la hagaajiyaa.

Mabda'a hawlgalka firdhiyehu wuxuu ku salaysan yahay isticmaalka isku-darka-xawaaraha sare leh ee wax-shiidka si fiican u shiidi badeecada ilaa tiro isku mid ah laga helayo.

Faahfaahinta Alaabta

01. Rack Host 02. Main Motor 03. Matoorka ugu muhiimsan ee kor u qaadida hydraulic, kor u qaadida istaroogga 1.1M-1.6M 04. Shafka kala firdhisanaanta birta 05. Haydarooliga 06. Xakamee sanduuqa korontada

XAAFADDA CODSIGA

Kala-firdhiye-xawaaraha sarreeya wuxuu ku habboon yahay isku-darka, kala-firdhinta, iyo kala dirida dareeraha iyo walxaha dareeraha ah ee warshadaha kiimikada sida dahaarka, midabada, midabada, iyo khadadka.

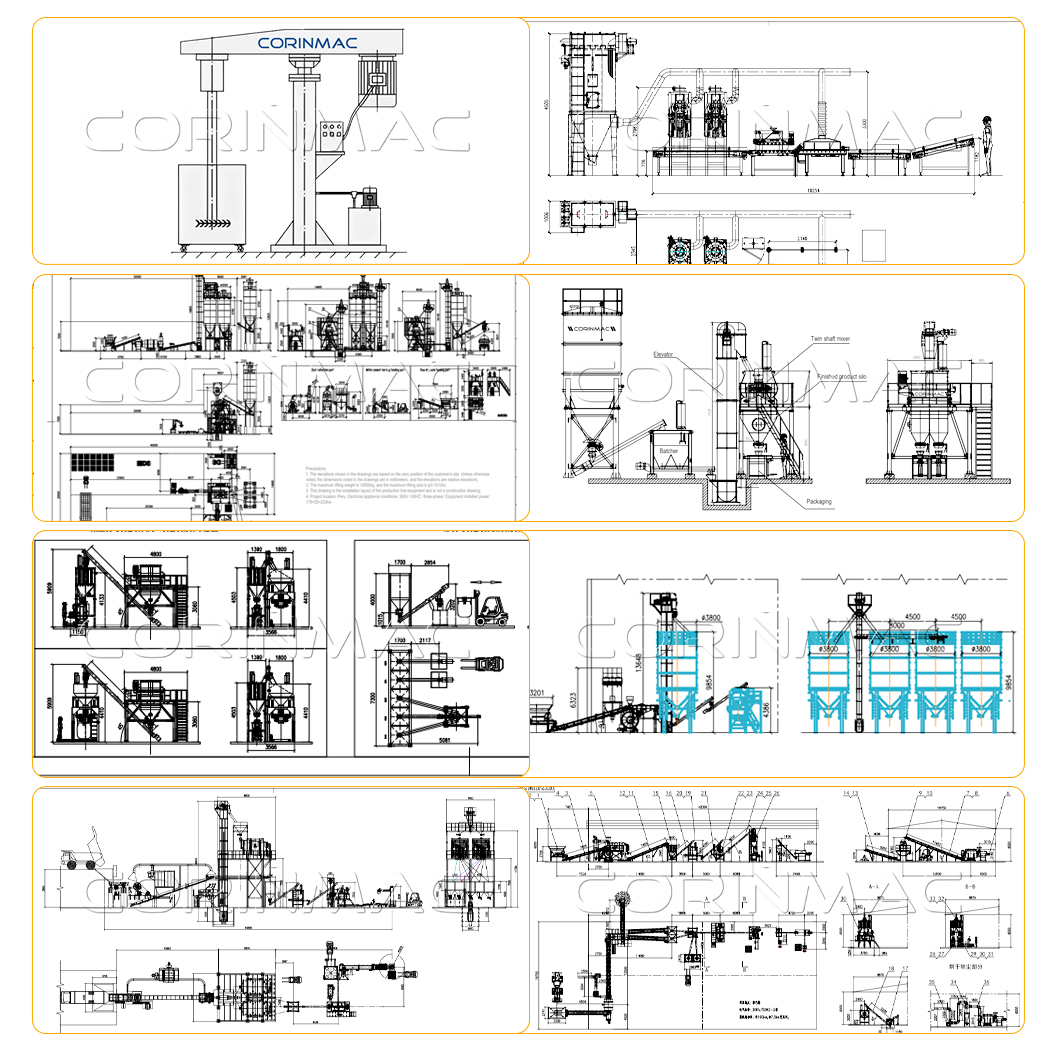

1 ilaa 1 adeeg la habeeyey

Waxaan samayn karnaa naqshado iyo qaabayn barnaamij oo kala duwan iyadoo loo eegayo shuruudahaaga. Waxaan siin doonaa macmiil kasta oo leh xal-soo-saarka habaysan si loo daboolo shuruudaha goobaha dhismaha ee kala duwan, aqoon-is-weydaarsiyada iyo qaabka qalabka wax-soo-saarka.

Mashruuc lagu guulaystay

Waxaan ku leenahay goobo badan oo mawduucyo ah in ka badan 40 waddan oo adduunka ah. Qayb ka mid ah goobaha rakibadeena waa sida soo socota:

Halbeegyada

| Qaabka | Awood | Xawaaraha wareega | Dhexroor gooyn | Mugga weelka/wax soo saarka | Awoodda matoorka Haydarooliga | Dhererka qaadida gooya | Miisaanka |

| FS-4 | 4 | 0-1450 | 200 | ≤200 | 0.55 | 900 | 600 |

| FS-7.5 | 7.5 | 0-1450 | 230 | ≤400 | 0.55 | 900 | 800 |

| FS-11 | 11 | 0-1450 | 250 | ≤500 | 0.55 | 900 | 1000 |

| FS-15 | 15 | 0-1450 | 280 | ≤700 | 0.55 | 900 | 1100 |

| FS-18.5 | 18.5 | 0-1450 | 300 | ≤800 | 1.1 | 1100 | 1300 |

| FS-22 | 22 | 0-1450 | 350 | ≤1000 | 1.1 | 1100 | 1400 |

| FS-30 | 30 | 0-1450 | 400 | ≤1500 | 1.1 | 1100 | 1500 |

| FS-37 | 37 | 0-1450 | 400 | ≤2000 | 1.1 | 1600 | 1600 |

| FS-45 | 45 | 0-1450 | 450 | ≤2500 | 1.5 | 1600 | 1900kii |

| FS-55 | 55 | 0-1450 | 500 | ≤3000 | 1.5 | 1600 | 2100 |

| FS-75 | 75 | 0-1450 | 550 | ≤4000 | 2.2 | 1800 | 2300 |

| FS-90 | 90 | 0-950 | 600 | ≤6000 | 2.2 | 1800 | 2600 |

| FS-110 | 110 | 0-950 | 700 | ≤8000 | 3 | 2100 | 3100 |

| FS-132 | 132 | 0-950 | 800 | ≤10000 | 3 | 2300 | 3600 |

Xogta Shirkadda

CORINMAC-Iskaashi & Guul-guulaysi, kani waa asalka magaca kooxdayada.

Tani sidoo kale waa mabda'ayada hawlgalka: iyada oo loo marayo wada-shaqeyn kooxeed iyo iskaashi lala yeesho macaamiisha, u abuurno qiime shakhsiyaadka iyo macaamiisha, ka dibna garwaaqsada qiimaha shirkadeena.

Tan iyo markii la aasaasay 2006, CORINMAC waxay ahayd shirkad wax ku ool ah oo hufan. Waxaa naga go'an inaan helno xalalka ugu fiican ee macaamiisheena anagoo siinaya qalab tayo sare leh iyo khadadka wax soo saarka heer sare ah si aan uga caawino macaamiisha inay gaaraan kobaca iyo horumarka, sababtoo ah waxaan si qoto dheer u fahamsanahay in guusha macaamilka ay tahay guushayada!

booqashooyinka macaamiisha

Ku soo dhawoow CORINMAC. Kooxda xirfadleyda ee CORINMAC waxay ku siinaysaa adeegyo dhammaystiran. Si kasta oo dalka aad ka timid, waxaanu ku siin karnaa taageerada ugu tixgelinta badan. Waxaan khibrad dheer u leenahay warshadaynta hoobiyeyaasha qalalan. Waxaan la wadaagi doonaa waayo-aragnimadayada macaamiisheena waxaanan ka caawin doonaa inay ganacsi furtaan oo ay lacag sameeyaan. Waxaan uga mahadcelineynaa macaamiisheena kalsoonidooda iyo taageeradooda!

Jawaabcelinta Isticmaalaha

Alaabtayadu waxay ku guuleysteen sumcad wanaagsan iyo aqoonsi in ka badan 40 waddan, oo ay ku jiraan Maraykanka, Ruushka, Kazakhstan, Kyrgyzstan, Uzbekistan, Turkmenistan, Mongolia, Vietnam, Malaysia, Saudi Arabia, United Arab Emirates, Qatar, Peru, Chile, Kenya, Libya, Guinea, Tunisia, iwm.

Rakibaadda iyo hawlgelinta

CORINMAC waxay bixisaa adeeg ku rakibida goobta iyo hawlgelinta. Waxaan u diri karnaa injineero xirfad leh goobtaada si waafaqsan shuruudahaaga waxaanan tababari karnaa shaqaalaha goobta si ay ugu shaqeeyaan qalabka. Waxaan sidoo kale bixin karnaa adeegyo hagitaan rakibidda fiidyowga.

sawirid

Alaabtayada

Alaabooyinka lagu taliyay

Xawaaraha la hagaajin karo iyo kala firdhiye hawleedka deggan

Kala-saaruhu wuxuu leeyahay shaqooyinka kala firdhinta iyo kicinta, waana badeecad wax-soo-saar ballaaran; waxay ku qalabaysan tahay beddelaha inta jeer ee loogu talagalay xakamaynta xawaaraha stepless, kaas oo socon kara wakhti dheer, oo leh hawlgal xasilloon iyo buuq yar; saxanka kala firdhiya waa sahlan tahay in la kala diro, waxaana lagu bedeli karaa qaabab kala duwan oo saxannada kala firdhiya iyadoo loo eegayo habraaca habraaca; qaab-dhismeedka wax-qaadista wuxuu qaataa dhululubada hydraulic sida jileeyaha, qaadista waa mid deggan; Alaabtani waa doorashada koowaad ee firidhsanaanta dareeraha adag iyo isku dhafka.

Soosaaruhu wuxuu ku habboon yahay soo saarista qalabyo kala duwan, sida rinjiga cinjirka ah, rinjiga warshadaha, qalin biyaha ku salaysan, sunta cayayaanka, koollada iyo qalabyada kale ee leh viscosity ka hooseeya 100,000 cps iyo content adag oo ka hooseeya 80%.

wax badan aragCRM Taxanaha Ultrafine Shiididda Mill

Codsiga:Kaalshiyamka kaarboonaytiga burburinta, farsamaynta budada gypsum, desulfurization warshad korantada, miiqinta macdanta aan birta ahayn, diyaarinta budada dhuxusha, iwm.

Qalabka:dhagax nuurad, calcite, calcium carbonate, barite, talc, gypsum, diabase, quartzite, bentonite, iwm.

- Awoodda: 0.4-10t/saacaddii

- Wanaajinta alaabta dhammaatay: 150-3000 mesh (100-5μm)

Kharash-ku-ool iyo raad yar oo tiirar ah...

Awood:~500 oo bac saacaddii

Tilmaamaha & Faa'iidooyinka:

1.-Suurtagalnimada in paletteing laga soo qaado meelo badan oo laga soo qaadayo, si loogu maareeyo bacaha khadadka bacaha kala duwan ee hal ama in ka badan.

2. -Suurtagalnimada in palette lagu jeexjeexo gogosha si toos ah dhulka loo dhigay.

3. -Xajmiga aad u kooban

4. -Mashiinku wuxuu leeyahay nidaamka hawlgalka PLC-control.

5. -Barnaamijyada gaarka ah, mishiinku waxa uu qaban karaa gabi ahaanba nooc kasta oo ah barnaamijka palletizing.

6. -Qaabka iyo isbeddelka barnaamijka waxa loo fuliyaa si toos ah oo degdeg ah.

Hordhac:

Palletizer tiirka waxa kale oo lagu magacaabi karaa Rotary palletizer, Single Column palletizer, ama palletizer-ga isku xidhka, waa nooca ugu kooban uguna cufan ee palletizer. Saxiixa sariiraha waxa uu xamili karaa bacaha ay ku jiraan alaab dagan, hawoday ama budo leh, taas oo u ogolaanaysa in qayb ahaan isku darka bacaha lakabka ee labada sare iyo dhinacyada, bixiya isbedel qaab dabacsan. Fududnaanteeda aadka u daran waxay suurtogal ka dhigaysaa in palettes lagu dhufto xitaa sariiraha si toos ah u fadhiya dhulka.

Iyadoo loo marayo barnaamijyo gaar ah, mashiinku wuxuu qaban karaa ku dhawaad nooc kasta oo ah barnaamijka palletizing.

Palletizer tiirka waxa uu leeyahay tiir wareegeysa oo adag oo leh cudud toosan oo adag oo ku xidhan taas oo si toosan ugu simbiri karta tiirka. Cududda jiifta waxa ay korkeeda ku rakiban tahay bac-qaadista oo ku dul dul dul-banaysa oo ku dul wareegaysa dhidibkeeda toosan. Qaboojiyaha waxa uu ku dul wareegayaa cududda oo ku wareegta tiirka weyn si uu u dhigo bacda meesha uu u qoondeeyay qaabka paletteing ee barnaamijka ah.

wax badan aragXakamaynta wax-soo-saarka hoobiyeyaasha qalalan ...

Astaamaha:

1. Nidaamka hawlgalka ee luuqadaha badan, Ingiriisi, Ruush, Isbaanish, iwm. ayaa loo habeyn karaa iyadoo loo eegayo shuruudaha macaamiisha.

2. Interface hawlgalka muuqaalka.

3. Xakamaynta caqliga si toos ah oo toos ah.

Khadka wax soo saarka qalajinta oo leh tamar hoose

Tilmaamaha iyo Faa'iidooyinka:

1. Dhammaan khadka wax-soo-saarka ayaa qaata xakameyn isku-dhafan iyo is-dhexgal muuqaal ah.

2. Hagaajin xawaaraha quudinta alaabta iyo qalajiyaha xawaaraha wareegta ee beddelka soo noqnoqda.

3. Gubi xakamaynta caqliga, shaqada xakamaynta heerkulka caqliga leh.

4. Heerkulka alaabta la qalajiyey waa 60-70 digrii, waxaana si toos ah loo isticmaali karaa iyada oo aan qaboojin.